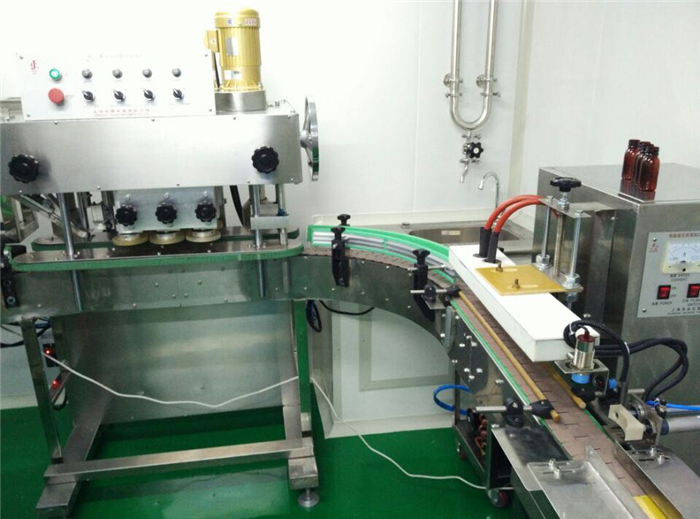

Automatic filling machine widely used in

petrochemical, daily chemicals, pharmaceutical, food, pesticide and other

industries in the packaging line. It adopts stepless speed regulation, the

machine is adjustable for different size of bottle.

This machine adopts PLC control, sthe

filling volume adjustment, filling speed, the entire equipment system can be

completed by a single click on 5.7 inches touch screen, convenient and direct.

Easy foaming material, with a lifting nozzle reduce material foaming.

Linear filling machine this machine for

quantitative automatic filling machine, can be used in filling paste, dilute

paste, used in the design of mechanical linear motion mode, and using the PLC

logic controller , sensor and cylinder, to achieve the purpose of automatic

control equipment, machine are made of 304 stainless steel material, Aluminum

Alloy frame completely conforms to the GMP standard. The equipment is easy to

operate and can be filled with different containers in a short time to achieve

the cost-effectiveness of one machine

1,adopt PLC programmable control

2, with 5.7 inches color touch screen

man-machine interface system

3, the filling volume adjustment, filling

speed, the entire equipment system can be completed by a single click on touch

screen, convenient and direct

4, easy foaming material, equip with

lifting nozzle to reduce material foaming

5. The filling structure is simple, the

adjustment is convenient, the size bottle is universal, the bottle shape is

changed, no need change any parts of machine.

6, can equip with complete package line.

The metering cylinder of the filling

machine is respectively connected with the filling head, and through the

reciprocating movement of the main cylinder, a quantitative liquid, a half

fluid and a paste are sucked in, and then injected into the container to be

loaded. In this process, it is necessary to switch a through valve to change

the flow direction of the liquid when the main material cylinder changes in

time. Moreover, in the injection process, in order to speed up the filling

speed without causing the liquid to overflow, when filling to the full bottle

of 90%, it is necessary to open a connected throttle valve in the injection

path, so that the flow of injection is significantly reduced. Then finished

filled bottle move out, new empty bottle move in, in this process, accurately

and timely control the stop plate installed on conveyor for bottle entrance and

exit, ensure each time in and out of the container, and at the same time to

ensure that the container regardless of shape, the filling head can be exactly fitting

with container mouth, otherwise the output alarm signal, and before the fault

is not excluded, not to continue filling. Easy foaming material, equip with a lifting

nozzle to reduce material foaming. Finally, the filling head can be moved down

accurately after the container is in place to fill the bottle mouth. After

filling, the filling head should be moved rapidly so that the container can be

output smoothly.

|

Item |

Parameter |

|

Filling Volume Range |

50ML-5000ML(Customized Available) |

|

Filling Speed |

10-15 bottle /min |

|

Filling Accuracy |

±1% |

|

Voltage |

220V/50HZ—60HZ |

|

Power |

500W |

|

Air Pressure |

5~6kg/ cm 2 |